If you’ve been boating for any length of time, you probably have a pretty good idea of how trolling motors work.

You know that if they’re too deep in the water, they may scrape the bottom of a shallow body of water or be damaged by other obstacles.

But if they’re not deep enough under the water, they may come up above the surface, or cavitate, especially in choppy waters.

So what is the ideal depth for a trolling motor?

What happens when a trolling motor is left running when it’s not underwater?

And can you shorten the shaft of a trolling motor to make it better fit the size of your boat?

Keep reading to find answers to all of these questions!

Table of Contents

What is the Best Depth for a Trolling Motor?

The answer may vary depending on the boat, whether you have a bow mount or transom mount trolling motor, and the average water conditions you’re dealing with.

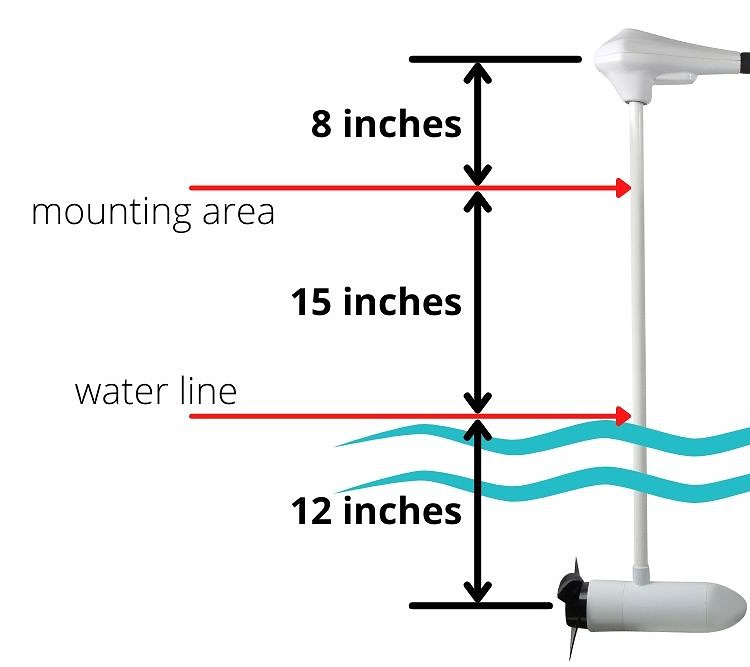

In general, though, the top part of the trolling motor head should be about 12 inches below the surface of the water.

With that in mind, you might think you can just measure from the place you plan to mount the trolling motor down to the water line, then add 12 inches to determine the proper shaft length. But it isn’t quite that simple.

You also need to account for the part of the shaft that may stick out above the boat, the part attached to the controls.

Also, the motor head must be submerged at least 12 inches. That means the top part will be at the 12-inch line, while the rest of the motor head will hang down below that line.

To determine the proper shaft length to ensure the motor head is at the correct depth, measure from the mounting area to the water line, then add 20 inches.

For example, If the distance from the mounting area to the water line is 15 inches, add 20 inches to that number. The shaft length you’ll need to keep the motor head submerged at the appropriate depth is at least 35 inches.

If you frequently fish or boat in rough waters, you may even want your motor a little bit deeper. Add an additional 5 inches to the sum above.

If your trolling motor has controls that you operate from a standing position, the shaft will have to be even longer because more of it will be above the boat. Add an additional 12 inches.

Can You Run a Trolling Motor Out of Water?

The short answer is, yes.

The motor will run just as well out of water as if it were submerged.

However, there’s no reason to run a trolling motor out of the water. Doing so will waste the battery and may cause damage to the motor.

Besides, why would you want to run it out of water? A trolling motor’s entire purpose is to push or pull a boat through the water. There isn’t much it’s good for once you take it out of the water.

That said, if the motor happens to cavitate in choppy water or because the shaft is too short, this brief exposure to air will not hurt the motor or cause it to shut off.

It will, however, be inefficient and may startle any fish in the area.

To keep your trolling motor from experiencing cavitation, make sure the motorhead is deep enough under the surface. Remember, keeping the motorhead deep enough is especially important when you’re dealing with rough waters.

Can I Shorten the Shaft on my Trolling Motor?

So you’ve determined that your trolling motor’s shaft is too long. Maybe it hangs down far below the water surface and you’re afraid it will become damaged.

Is there any way to shorten the shaft?

With most trolling motors, it is possible to cut off a part of the shaft to make it whatever length you need. However, it’s important to know what you’re doing before you start. It’s easy to damage the shaft and the wires inside if you’re not careful.

To shorten a trolling motor shaft, first remove the motorhead and control head, disconnecting any wires as necessary.

If possible, you’ll want to remove the wires that run up the length of the shaft. If you can’t remove them completely, at least move them further up the shaft, above the area you plan to cut.

You’ll need to know ahead of time exactly how long you want the shaft to be. If you’re changing a 42-inch shaft to a 36-inch shaft, you’ll be cutting six inches off one end of the shaft. It doesn’t matter which end you cut, as long as you’re able to replace the motorhead and controls.

Use a cutting tool to cut off the excess shaft.

Depending on the type and style of trolling motor, you may need to drill a couple of screw holes before you can reattach the motorhead or controls. Double-check that you’re aligning everything properly, mark the spots for the screw holes and use a power drill to create them.

Again, be very careful throughout the process. If any of the wires or connections are damaged, you may not be able to repair them. Become familiar with the process before you begin disconnecting and cutting. This video may be helpful.

It’s also worth noting that, while you can shorten a trolling motor shaft, you probably won’t be able to lengthen one.

The cords that run up the shaft can’t easily be made longer, and it would cost a significant amount of time and money to replace the necessary parts. In such cases, you would probably be better off simply buying a larger trolling motor.

Conclusion

And there you have it!

Setting your trolling motor at an appropriate depth will help it to function properly, while at the same time reducing the risk of it becoming damaged.

Remember, the general rule is to keep the motor submerged 12 inches below the waterline.

Next time you’re out on the water, you can feel confident knowing that your trolling motor is at the ideal depth for your boat and water conditions.

I created this site to help people – to help you – with your boat problems. Instead of helping one person at a time, I want this website to be the “one-stop-shop” for everyone’s boating concerns. Read more.