If you’re just getting into the world of RIB boats, you might be interested in finding out how they are made.

In this article, we will answer that question for you.

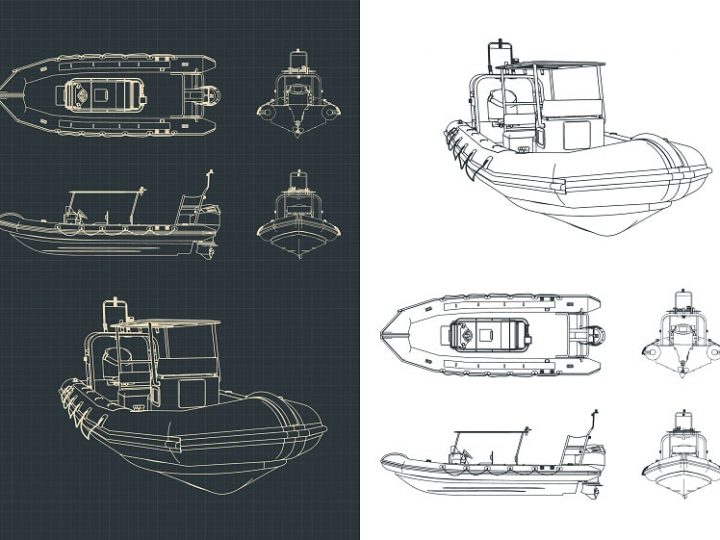

Rigid inflatable boats(RIB) come in different shapes and sizes but are always lightweight.

They are capable of high performance, with a hull made from either fiberglass or aluminum.

Those composite materials are surrounded by inflatable materials such as rubber and PVC.

If you are curious about a more detailed look into how RIB boats are made, keep reading.

We will be going over it in the rest of this article.

Table of Contents

How Are RIB Boats Made?

As their name implies, rigid inflatable boats (RIB) have a rigid frame that supports inflatable materials.

This makes them highly versatile and basically ensures that they won’t sink.

RIB boats are sturdy, but at the same time, they offer high maneuverability.

The majority of RIB boats are between 13 and 28 feet long and have either one or several motors.

Those motors can either be inboard or outboard.

They can also vary in power greatly.

The weakest RIB boat will have only 5 horsepower, while the strongest ones can go up to 300 horsepower.

Hull

The hulls of RIB boats are made from composite materials. These include aluminum, fiberglass, steel, wood, or a combination of fiberglass and wood. Sometimes, even Kevlar can be used to add more endurance to the hull.

These hulls are shaped with hydroplaning in mind, so they need to be able to freely glide across the water under any type of condition.

We differentiate between so-called “deep-V” hulls and “shallow-V” hulls. The former is more comfortable to ride because they can cut through waves without any issues. However, this requires much more engine power.

“Shallow-V” hulls achieve much lower speeds and are less comfortable because of it, but their engines are weaker and cheaper.

These are two design choices most RIB boat makers have to make.

However, recent times have seen the appearance of an “all-around” RIB hull that combines the two in a way.

It has a “deep-V” hull at the bow, but it starts to flatten out to become more shallow near the rear parts. This allows the RIB boat to be more stable.

Tubes

The tubes, the inflatable parts of a RIB boat, are generally made in several separate sections. This is done to prevent sinking in case of a puncture on one of those sections. By partitioning the tubes, these boats are safer to ride and easier to fix.

Each of these partitioned sections has its own valve that allows you to add or remove air from it. Newer boats also allow you to release pressure by using separate valves.

Larger RIB boats (23 feet and more) usually have six chambers at a minimum, but generally even more than that. Every single one of these chambers has its own valve and pressure release.

RIB boats have more redundancy with extra chambers. This means that if a single chamber gets damaged (by a puncture for example), the impact on the entire boat is lesser than it would be if it had fewer chambers.

RIB boats that have pressure-release valves are at an advantage when it comes to security.

As the temperature increases inside the tubes, they will begin to expand. This is when the pressure-release valves will open up and prevent the tubes from exploding.

Tubes are generally made from Hypalon or PVC (Polyvinyl chloride), although sometimes PU (Polyurethane) will be used.

Hypalon

The name Hypalon is used for Chlorosulfonated Polyethylene or CSM.

Tubes that are made with this material are extremely easy to mass-produce. They are also easily repairable by using the simplest kits for puncture repairs.

No tubes are made out of pure Hypalon because the material is not airtight. This is why it is always combined with neoprene when it is used to manufacture tubes.

One advantage of these tubes is that they last for a very long time, up to 20 years. Hypalon tubes can last twice as long as PVC tubes.

Hypalon is the most commonly used material for RIB tubes that are produced in the UK.

PVC – Polyvinyl Chloride

When used for tube manufacturing, PVC has one downside, and that is that it lacks flexibility. For that reason, a polymer is used in combination with PVC to make the tubes more elastic.

Polymer vaporizes with time which makes the PVC fragile and it begins to crack. PVC tubes are the cheapest and they can last up to 15 years, but normally they last 10 years on average.

Some advantages to PVC are that it is quite cheap, so these tubes are more affordable, and they can be welded, which means these tubes won’t leak as often or blow out.

PVC tubes are generally really well made with these welded seams.

There is also a new kind of PVC called Valmex. It contains a black layer on the inner side which reduces UV damage.

Polyurethane

Polyurethane (PU) tubes are not easy to produce so they are less common in the manufacturing of RIB boats. This material is extremely durable, which is its main advantage. Oftentimes these tubes will be bulletproof or knife-proof.

Older polyurethane tubes would age really fast, but new models are extremely impervious to deterioration. They have a black layer that helps them reduce the damage of UV rays.

Polyurethane tubes are thermally welded, but they still use adhesives in their bonds. They can last well over 20 years and are commonly found on commercial RIB boats.

These boats often need extended durability and tube replacement can be quite expensive.

Wheelhouse and Cabin

Bigger RIB boats sometimes have wheelhouses that are made of Glass Reinforced Plastic or aluminum. They offer protection from bad weather for the crew and passengers of the boat. They can also be used to protect expensive equipment that is used on the RIB.

There are also RIB manufacturers that offer boats with wheelhouses that can be removed when the weather is nice. These RIBs are usually used in Scotland or Ireland.

Another new-ish trend is RIB boats with small cabins. These cabins can generally accommodate two people and contain chemical toilets. This adds another function to RIBs, making them suitable for longer cruises.

Which is Better – PVC or Hypalon?

This question is hard to answer because both of these materials offer certain advantages and disadvantages. We’ll get straight to the point and say that there is no clear winner here.

However, we can help you by giving you the characteristics of each material, so you can decide for yourself which one suits you better.

PVC

- Lacks flexibility

- Combines with polymer to add elasticity

- The polymer will vaporize with age so the tubes will crack

- Lasts approximately 10 years, although sometimes it can go up to 15

- The cheapest option

- It can be welded so it isn’t prone to leaks

- Extremely convenient as it can be folded without worry

- Newer versions have a layer that prevents damage from UV rays

- Comes in many different colors

Hypalon

- Easy to manufacture

- It can be easily repaired with basic repair kits

- It is not airtight so it is commonly combined with neoprene

- Tubes can last up to 20 years

- More durable than PVC

- Can resist abrasion, chemicals, and high temperatures

- Much harder to fold than PVC, and folding isn’t good for this material

Who is The Best RIB Maker?

This is yet another question that can be hard to answer since there are many manufacturers that make high-quality RIBs. We will name a few of our favorites here; the rest is up to you.

Zodiac Boats

Zodiac Boats are the inventors of the inflatable boat, with their first model dating all the way back to 1896. They keep coming up with new models and new ideas, and it is always smart to keep an eye out for what they have to offer.

Zar Formenti

This is an Italian brand that was founded in 1992 by Piero Formenti. The brand reached the US in 2009 and left quite a mark on the RIB boat scene. They patented a fiberglass hull which makes sailing go much smoother and makes it easier to sail through rough seas.

Technohull

Just like the previous name on our list, this is another company that originated in the Mediterranean. Technohull also started making an impact in the US with their fast boats that are easy to maneuver.

Other Options

These are just some of the manufacturers we recommend. If you aren’t happy with what they have to offer, here are some other names to look out for:

- Airship

- Ribcraft

- BRIG

- Sealegs

- Williams Tender

- Jetsurf USA

- Argos Nautic

- Tornado Boats International

Conclusion

There you go; that’s basically all you need to know about how RIB boats are made.

We covered all of the important parts, from various tube materials to the comparison of PVC and Hypalon – the most popular materials.

By understanding how these boats are made, you can pick one for yourself more easily. If you have any questions leave a comment below!

I created this site to help people – to help you – with your boat problems. Instead of helping one person at a time, I want this website to be the “one-stop-shop” for everyone’s boating concerns. Read more.